San Rafael Swell & Southern Utah

San Rafael Swell and Southern Utah Region

November 13 & 14

2020

This adventure was Scary Life Threatening Amazing

This adventure began like all my other trips: plan a destination, find a camping spot, buy food, pack up gear, and fuel up the car. But, as it normally turns out, it didn’t go as expected.

“Better to have it and not need it, than to need it and not have it”. Woodrow F. Call

This isn’t just a great motto to live by. This is a phrase I take very seriously if I go on a trip by myself. I have plenty of food, water, and fuel, and I always tell someone where I’m going and when to expect a text or phone call when I’m finished. So, make sure you do the same! I started this adventure early in the morning in Northern Utah where I live. I had already packed my car the night before and went to the store to buy ice for my cooler. After buying ice and a few extra snacks I filled up my cooler and headed south. It only takes about 4 hours to get to what we call, The Swell. It’s a beautiful drive through Spanish Fork Canyon and I love seeing all the remnants of the once booming mining operations along the way and especially when you near the town of Helper. I drove through Price and eventually stopped to top-off the gas in the small town of Wellington.

Back on the road, I continued down Highway 191 from Wellington to the junction with I-70. It is just over 50 miles to the junction, and it’s another 8.4 miles to Utah State Road 24 (look for the signs pointing you to Hanksville and Goblin Valley State Park.

Since it was still early in the day I drove straight to my first adventure: petroglyph hunting in some random canyons! This may not sound like a lot of fun to you, but to me, it sounds like a great time! I had already scouted out about 20 possible locations on a map and saved the GPS coordinates on my phone, so I could easily reference them while I was hiking.

I knew there were already some rock art in the area to the west at Temple Mountain and also to the east of me in Horseshoe Canyon, so it was possible that rock art could be found in these other nearby canyons and alcoves. I didn’t know too much about this area beforehand besides it was remote and I would need to be extra careful while far away from towns and people. This was fine with me, since I have personal rules that I strictly follow if I hike alone. Here are a few of them:

- Don’t enter slot canyons alone

- Don’t get close to any cliff edge

- Don’t do anything that requires using a rope to climb higher than a few feet

- Don’t enter any mines or caves alone

- Always document my trail with a GPS tracking map

I got to where I wanted to be by about noon. I parked the car, grabbed my gear, and headed out. There wasn’t really a trail to follow. I was mostly following dry washes and/or hiking on the open desert. I did find an old off-road trail that was nice to follow. It saved me from stepping on cactus! But, this trail was overgrown and I was again walking where it was easiest.

I checked out the first sets of GPS coordinates and didn’t see any rock art, but I did find a neat small canyon that I thought I would have time to explore, but I added it to my own “to-do” list for next time. I kept finding random pieces of metal and even some circles of rock on top of the canyons.

I also found a cool glass bottle. These were probably from a bored cowboy, but who knows! I love seeing this bit of history because it tells a story. We may never know what the circle of rocks mean, but it made me stop and take a picture of it!

While stopping for a drink, I checked my topography maps and saw some text that said “natural arches”. Since my petroglyph hunting wasn’t going so well, I decided to hike over to the natural arches and get some pictures. I could see the first arch from a distance and it looked promising. The hike to the arch would require a little route planning to avoid some steeper areas.

From on top of the mesa, I planned a route zig-zagging down to the canyon floor, then across the canyon, then up directly to the arch – easy enough. I then hiked into the canyon and saw what appeared to be evidence of some springs. I checked out the springs and found very small water seeps under a few alcoves. Then I hiked towards the first arch and discovered it was up inside a small cove, and I can’t think of a good name for it yet. (Later, I checked on a few websites that are databases for natural arches around the world and didn’t see either of these two listed. I guess that means we can name them?

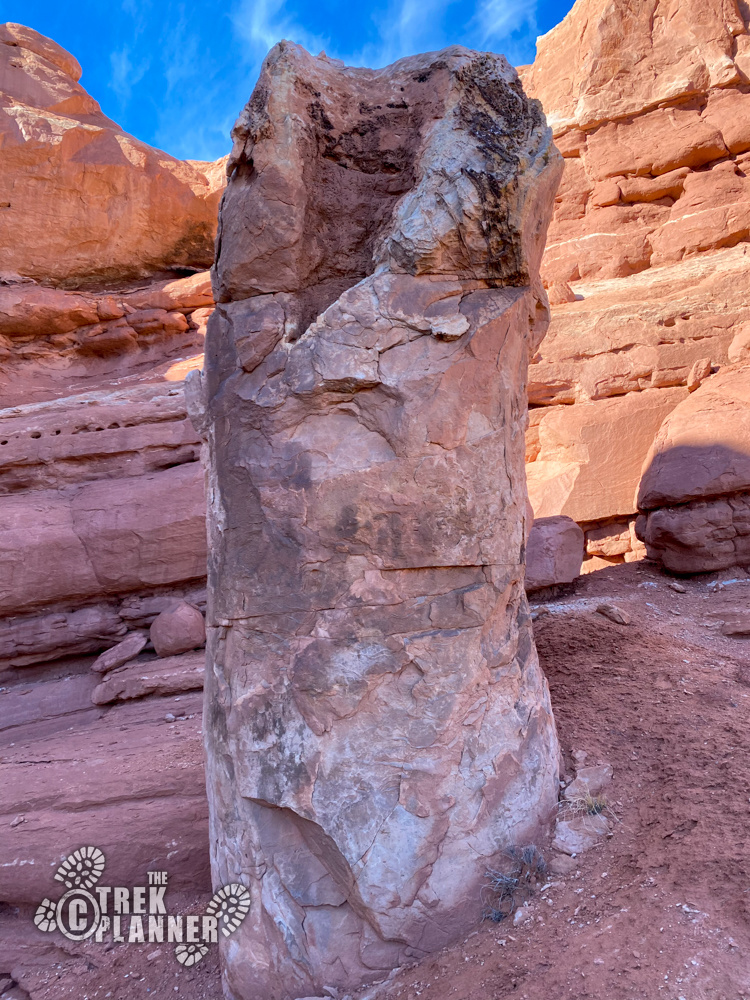

After taking pictures I found a weird cylindrical-type rock up near some cliff walls around the corner. It seemed very random and out-of-place and I was fascinated by how it formed here. It was about 15 ft. tall. I spotted another one of these pillars on the other side of the canyon. The center of the canyon began to narrow down at this point into a slot canyon, so I went safely to the other side to see if I could get a glimpse of the other natural arch on my map.

I did see the other arch and I decided to hike over to it. I found a nice sloping ramp back down the canyon and it went back up the other side. I got up-close to the other arch and saw that there were three different openings in the arch. I wanted to get even closer to get some good pictures, so I found another safe route to the top and went up.

Just before I made my ascent, there was a minor tricky part that required me to stand about 3 ft. up on a narrow ledge before jumping over to a wide rock so I could access my route to the arch. As I was maneuvering on this narrow ledge, I was using my hands to find a good place to hold on to when I heard a voice inside my mind say “don’t grab on this rock”.

I immediately pushed the thought away because I was only about 3 ft. in the air and still felt perfectly safe. I grabbed onto this same rock and began to put a little more of my weight on it so I could pull myself over to where I wanted to be. I again heard the voice, “don’t grab this rock”, but it was much louder in my mind. I didn’t pay attention to it again and then put almost all of my weight on this rock trying to pull myself up and then I hear a very loud “look out!”

And right when I put all my weight on my handhold (but still keeping my feet planted), the rock breaks out of it’s holding spot and falls crashing down right in front of me! As it fell, it grazed my knee and I was thankful to the universe for not letting me be in front of that rock like I originally was planning! Do you have moments like this, where you hear warnings in your mind that don’t seem like they are from you? The picture of the rock is circled below.

I continue on hiking up to the arch and got some great pictures of it! This particular arch has three separate windows, so I think I’m naming this one: Triple Arch! At this point I was already hiking for more than 3 hours and it would take me another hour to hike back to my car. The sun sets at like 5pm and I didn’t want to be far from my car in the dark even though I did have a flashlight.

I get back to my car and still have about 45 minutes of sunlight left – thankfully. I then drive the very long drive down to BlueJohn Canyon trailhead to take pictures of the old cabins and also of Granary Springs. You can see a small structure with three rooms near the spring. Someone spray painted “BJ’s Motel 6” on the front. There is a dugout shelter near this too. Both these structures are run-down, but are still used by campers and visitors. Some people think it’s a great idea to paint their names on these historical relics. I think it just shows they don’t have respect for it.

There were two other campers in this area and I was debating if I should camp way out here or go back to Temple Mountain where I originally planned on staying. I quickly scout out Granary Springs which is a very small spring, but did have a trickle of water. It was surrounded by a fence with a trailcam on one of the corner posts. I took some pictures and made the decision to go to Temple Mountain and camp there.

The Temple Mountain Campground has outhouses and picnic benches and I knew there would be lots of other campers. I made the long drive to Temple Mountain and set up camp. That night I cut three small fresh potatoes boiled them until they were soft. I then mashed them with a fork, added spices and butter, and then cooked up a bratwurst and mixed it all together = yum! It wasn’t very cold this night, but I did have a propane heater that I used for a few minutes to get the tent nice and warm.

At about 2am-5am this morning it was very windy, like, I’m talking about 20 MPH with up to 30 MPH gusts. You might not think 20 MPH is a lot, but when you’re in a tent, it’s violent. Good thing I parked my car in a way to shield me from most of the wind. I woke up about 10 times with huge gusts squishing my tent. At about 3 am I heard my chair outside flip over and ram into the tent. I put on my shoes and cleaned up my camp a bit so nothing else flies away. I somehow fell back asleep until about 7:30 am and woke up to no more wind. I had bananas, oranges, breakfast bars, chocolate, and sweet rolls for breakfast.

I got another early start this morning and headed out to the Robbers Roost area, again in the San Rafael Swell area. This area was a hideout for Robert LeRoy Parker (Butch Cassidy) and his Wild Bunch for some time. They are reported to have built several different cabins, corrals, small bunkers, and multiple hideouts inside this vast network of deep canyons and drainages. If it were the late 1890s, it would be almost impossible to find someone in Robbers Roost. Even today, with all our technology, it would be virtually impossible to find someone there now. It is a very remote area and I took it seriously.

Today I wanted to explore some areas where I thought Butch Cassidy would have stayed. If I were Butch Cassidy, I would hide in a place that was very close to spring water, provided shelter and safety, and was completely hidden from view from on top of the canyons. There are many places that fit this description, but there also needs to be a place where you could easily bring horses and cattle. I found a place that had three springs and hints of some historical relics. I plugged in the GPS coordinates and went out!

The drive to where I wanted to go in Robbers Roost took about 1.5 hrs from my camping spot. Robbers Roost is just west of Canyonlands National Park. There is the Hans Flat Ranger Station kind of close, but still plan on being alone out there. The road was nothing but dirt, but it was surprisingly in great condition. There were a few washboard parts, but overall, my 2-wheel drive car made it without high-centering or any sort of problems. I have read on other adventure websites that the Robbers Roost area was extremely difficult to traverse and it was just too dangerous to make it out here without a high-clearance Jeep or truck. I’m not sure the conditions these other people were experiencing, but on this particular trip, it was very easy and enjoyable. Just make sure you are prepared for anything as there are no services out here whatsoever

After driving the 1.5 hrs, I finally got to where I could see the canyon below where I envisioned Butch Cassidy and his gang would have hidden. This canyon had very wide spots that would be perfect for cattle and horses. I immediately saw evidence of water by the large water-loving cottonwood trees down the center of the canyon.

I also saw a group of cows hanging out near a bucket. I parked my car in a flat spot and got out to inspect the nearby spring. The spring had actual flowing water coming from it. This would have been a literal lifesaver then as it is now. Imagine a desolate landscape with very little water and you come to this place and there was a spring with actual running water. You could live here for a very long time! Some websites believe that this was the place Butch Cassidy stayed after his train robbery in Castle Gate.

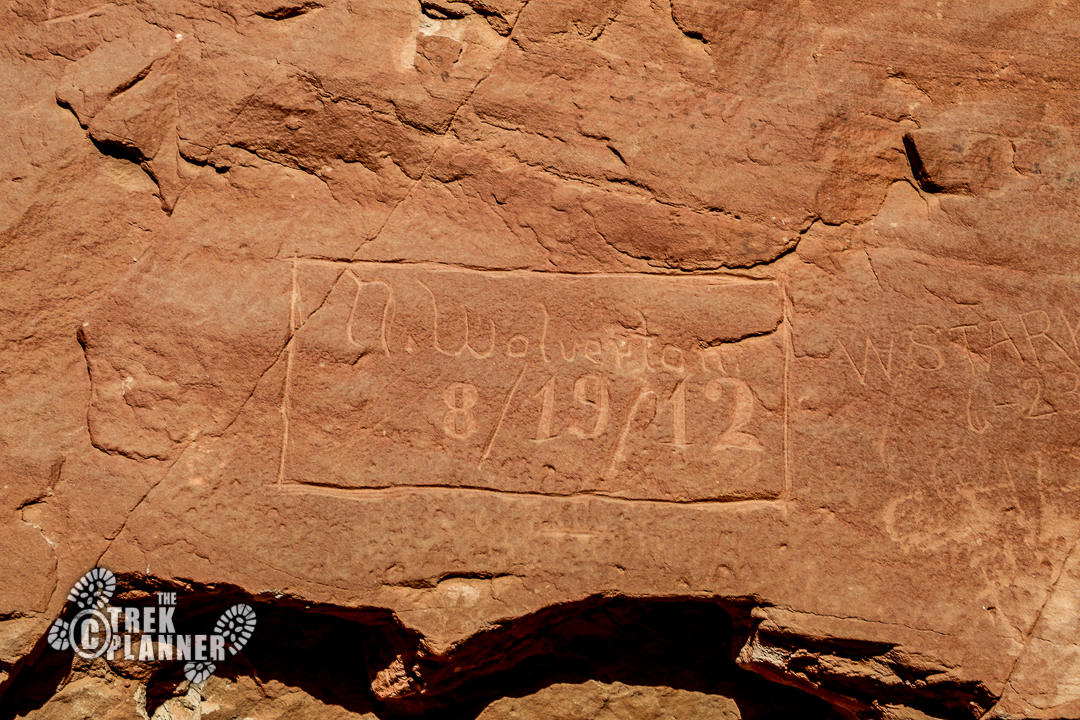

I walked down the canyon a little ways and it got narrower. I found many historical names carved on the rock including an N. Wolverton from August 19, 1912. Also a Christen Nelsen from Oct 26, 1905. A little ways from these I saw “RR” with an infinity symbol with an arrow pointing to the RR. What do you think these mean? “Robbers Roost”, perhaps? The canyon eventually narrows completely down to a slot canyon. This is a canyoneering route and one that would be fun doing if I had the proper gear and was with a group of people. Maybe next trip! I saw some other interesting inscriptions on the rocks and headed to the top of the canyon.

On top of the canyon I saw a few rusted metal cans and some small piles of rocks. Not sure what to make of these, but something was here.

I hiked up the canyon and eventually saw some bullet holes in the side of the rock wall that say “ROB” (?). This was near an old rock fireplace that was once part of a cabin here. The rock fireplace is all that’s left of the cabin. Was this cabin used by Butch Cassidy and his gang? Some people think yes. Others say no, but that he just used the nearby springs and corral. Near here I saw the name “Frenchy” engraved on a rock.

I continued up the canyon to find another spring that had a very small amount of water in it. This spring was surrounded by a fence to keep the cattle out.

Up a little more ways was where some websites believe Butch Cassidy brought horses and cattle inside of this circular corral. The very old corral is in a complete circle with one entrance for them to enter. You would funnel the horses in and then seal off the entrance. The corral is made out of what appears to be cedar tree posts that must have came from on top of the canyons near the BlueJohn area. The corral posts are kept together by barbed wire still faithfully doing its job. I climbed up on the hillside and imagined this place busy with Butch Cassidy and other outlaws running around down here. It would be the perfect place to hide and no one would have a clue you were here.

From this vantage point, I saw what I thought was the third spring. I hiked straight to it and found a small grotto with the tiniest amount of water coming from it. I also saw fresh cougar (?) tracks and other small animal tracks. This amount of water from these springs is enough for many animals and birds in the area. It would be fun to set up a trailcam and see what animals visit!

I spent about 3 hours exploring this area and went back to my car to make lunch. The cows wouldn’t stop starring at me – I don’t blame them. They were probably wondering who this madman is and why he’s out here!

I decided to check out Hanksville next. Hanksville is a very small town just south of Temple Mountain and it sounded nice to get a cold soda and explore there. After fueling up and getting snacks, I made the very quick decision to drive south to a mine I’ve been wanting to see for a few months. On Google Maps, I found an old mining area that was full of what I thought were old cars and machinery! It looked like a very fun place to explore and it sounded much more exciting that what I had originally planned to do – not much!

The drive to the mine took me along the beautiful Utah State Route 95. You will pass some of Utah’s best scenery on this route including views of Lake Powell and the Colorado River. Once I passed Hite I still had about an hour of driving until the mine. I won’t be sharing the location of the mine because I had a very dangerous experience there and don’t want others to get injured or worse.

The canyon the mine is in is extremely remote and lonely, yet it’s beautiful and a place I’d love to come back and explore in a side-by-side. The canyon was long and winding, but the road was also in great condition. It was a mostly smooth dirt road and my car did wonderfully without any problem. I stopped to take some pictures of the canyon when I noticed a dust cloud in the distance. I figured it was just a group of Jeeps making their way down the canyon, but I would soon find out, it wasn’t a group of Jeeps…

After slowly winding around this canyon I finally got to my destination. Right from my car, I could see metal cables, tires, buckets, barrels, and even a truck that was half-buried in a dry wash. I grabbed my camera and took some pictures of the truck. I then noticed another car down the road from where I parked. The car was near the bottom of the canyon and I thought the owner was out exploring on the other side of the canyon somewhere.

I didn’t think anymore of it, so I continued my trek to where the old cars and machinery were. I could see large tailings piles and a water tank and I was just trying to imagine this place busy with mining activity. I could see an old road to the top of the tailings, but the trail had since been covered with landslides. I hiked another way to the top and it got steep! I stopped to catch my breath and enjoyed the silent canyon when all of a sudden I heard a distant yet clear voice say “…3…2…1…” and then KABOOM!!

Right in front of me, on top of the tailings, I heard and saw the loudest explosion I have ever heard in my entire life. I must have been 200 ft. away from it, but the explosion shook the entire canyon so much that rocks and small landslides came down from all over. The shockwave was so strong and I was so close to it that it knocked me to the ground. I started to yell and scream, but the people on top didn’t hear me. Maybe they had earplugs in? Who knew and who cares! There was a large dust cloud and it was at this moment I got out my camera and recorded it and started to slide down the hillside.

At first, I thought the mine caved in, but then I quickly realized that someone had lit off dynamite or some type of explosive! These people failed to check around before lighting it off and as a result I could have been killed! What were the chances of me wanting to visit here at this random time to experience an event such as this at this exact time? Was there going to be another explosion? Were they throwing dynamite? Were they blowing up old dynamite they found in a mine? I didn’t care to find out anymore. I couldn’t care less about those old cars now either. It’s not worth it.

I checked my surroundings to make sure no more rocks were tumbling around me and I started to make my way down, fast! I stopped one more time to listen to hear if there would be any more explosions and at this exact moment I heard another distant voice say “5…4…3…2…1” and then a much smaller BANG happened. It almost sounded like a blasting cap. I had my camera rolling and I got it on video.

I then ran straight down the hillside and got in my car. I rolled down the windows and waited for a second just in case another explosion would happen, when I saw a man in a white shirt walk near where the earlier explosion had happened. It looked like he was carrying something. I was pretty shaken from this experience and didn’t want to mess with these guys who had access to an explosive. The white shirt guy didn’t seem concerned to check for other cars below. I drive up the canyon a little bit and look back at where I once was. I could then see on top of the hillside those cars I had seen in the satellite photos! I pulled out my camera and attach my 300 mm lens and got some close photos of the vehicles! I also saw some pipes up from the cars.

After exiting the canyon, I just started driving. I got to the point where I was supposed to turn to Hanksville, but had the crazy idea to head east to Blanding. It was about 90 miles to Hanksville and only 35 to Blanding. I decided to head to Blanding and go up to Moab to camp for the night instead. Good thing I packed up all my gear before I left Temple Mountain! I know this way would add more miles, but the thought of seeing Moab and maybe exploring Arches the next day sounded really good right now. I eventually sent an email the Monticello office of the BLM to ask them about any active mining claims or people blowing up stuff in the canyon I was in. So hopefully, if it was an active mine, appropriate signs and fencing will be placed around it.

I drove past Bears Ears and eventually saw a sign that said Mule Canyon Ruin. Since I was still shaken up by the dynamite experience, I thought it would be good to get out of the car and explore this little ruin. This ruin was exactly what I needed at this moment. It was a very short walk and I saw some great ruins that resemble some I’ve seen in Mesa Verde or even Hovenweep. There was just enough remaining light that I got some good photos of these ruins. I got back in the car and went to Blanding.

It was about 6:30 pm when I got to Blanding and decided to just not stop, but go straight to Moab. On the way to Moab I got pulled over by a cop who informed me that my front right headlight was out. He was pretty cool and just gave me a warning. I hadn’t even noticed it was out, so I was grateful that he pulled me over.

I got to Moab at about 7:50 pm and found the nearest auto parts store (they were closing at 8 pm!) and bought a new headlight. I got some dinner and was looking for a place to camp at Willow Springs when I just had the thought to finish the drive all the way home tonight.

That mining explosion incident woke up me like you would not believe and I was still high on adrenaline. I got back on the road and drove the remaining 4 hours to Northern Utah. Feels good to be in my own bed!